Continuous cooling transformation

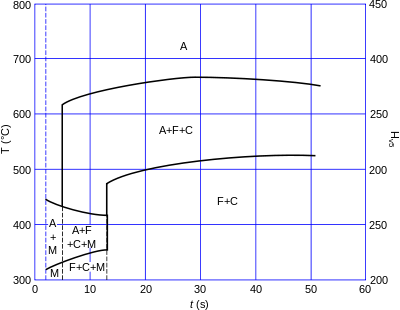

Continuous cooling transformation diagram of EN S355 (ASTM A-572 Grade 50, warranted yield stress 355 MPa) for welding (fast cooling, linear scale).

A continuous cooling transformation (CCT) phase diagram is often used when heat treating steel.[1] These diagrams are used to represent which types of phase changes will occur in a material as it is cooled at different rates. These diagrams are often more useful than time-temperature-transformation diagrams because it is more convenient to cool materials at a certain rate than to cool quickly and hold at a certain temperature.

Types of Continuous Cooling Diagrams

There are two types of continuous cooling diagrams drawn for practical purposes

- Type 1: This is the plot of transformation start, a specific transformation fraction and transformation finish temperature for all products against transformation time on each cooling curve.

- Type 2: This is the plot of transformation start, a specific transformation fraction and transformation finish temperature for all products against cooling rate or bar diameter of the specimen for each type of cooling medium.

References

- ↑ Transformation diagrams (CCT & TTT), retrieved 2008-04-17.

See also

| Wikimedia Commons has media related to Continuous cooling transformation diagrams. |

This article is issued from Wikipedia - version of the 5/25/2015. The text is available under the Creative Commons Attribution/Share Alike but additional terms may apply for the media files.