Jean-Baptiste Waldner

Jean-Baptiste Waldner (born 30 March 1959) is a French engineer, management consultant and author, known for his contributions in the fields of Computer-integrated manufacturing,[1] enterprise architecture,[2] nanoelectronics and nanocomputers.[3]

Biography

Waldner received his engineering degree in mechanical engineering from the Université de technologie de Belfort-Montbéliard in 1983, his Dr Engineer in Electronics in 1986 from the École Supérieure d'Électricité, and his Dr Eng. in Nuclear Science and Engineering in 1986 from the Institut National des Sciences et Techniques Nucléaires.

In 1986 Waldner started as consultant for the French Information Technology and Services company Bull, where he specialized in Computer Integrated Manufacturing (CIM). From 1990 to 1993 he was senior manager at Deloitte, senior partner at Computer Sciences Corporation from 1993 to 1996, Program Director for IT and Shared Services Centers at Carrefour from 1999 to 2001, and co-founded his own management consulting firm Waldner Consulting in 2004.

Work

Waldner's research interests ranges from Manufacturing Resource, Planning Computer Integrated Manufacturing and Enterprise Architecture, to Nanoelectronics and Nanocomputers.

Manufacturing Resource Planning (MRP/MRP2)

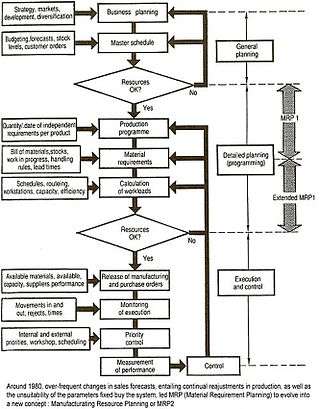

The Manufacturing Resource Planning concept has evolved over the past 30 years from a simple means of calculating materials requirements and components (which does not even take into account the production capacity of the company) - to integrated ERP MRP concepts and software to automated management of the entire company.[4]

During the 1980s the increasing changes of sales forecasts, which resulted in continuous and manual adjustments of the production plan, has in led to the MRP (Material Requirement Planning) model, which was strictly limited to the supply of materials. Eventually this evolved in means for wider production resources management, MRP2 (Manufacturing Resources Planning).[4]

Waldner (1992) showed, that MRP and MRP2 are essential principles of Computer Integrated Manufacturing (CIM). In the planning process of the enterprise they are the essential link between General Planning and execution and control. Thereby MRP2 covers three phases (see image):

- Production programme

- Material requirements,

- Calculation of workload

According to Oliveira (2003) the work of Waldner (1992) and others became "an important effort towards the goal of increasing the competitiveness of manufacturing companies through the introduction of automation and wider use of computers." [5]

Computer Integrated Manufacturing (CIM)

According to Waldner (1992) Computer Integrated Manufacturing is used to describe the complete automation of a manufacturing plant, with all processes running under computer control and digital information tying them together.[6] There are three major challenges to development of a smoothly operating computer-integrated manufacturing system:

- Integration of components from different suppliers: When different machines, such as CNC, conveyors and robots, are using different communications protocols (In the case of AGVs, even differing lengths of time for charging the batteries) may cause problems.

- Data integrity: The higher the degree of automation, the more critical is the integrity of the data used to control the machines. While the CIM system saves on labor of operating the machines, it requires extra human labor in ensuring that there are proper safeguards for the data signals that are used to control the machines.

- Process control: Computers may be used to assist the human operators of the manufacturing facility, but there must always be a competent engineer on hand to handle circumstances which could not be foreseen by the designers of the control software.

Machado et al. (2000) explained that "control, monitoring and supervision of industrial processes are increasingly demanding a great investment in technological solutions each time more embedded and with real-time capabilities, especially devoted to the interconnect, in an intelligent way, of shop-floor equipment with operational information systems."[7] This gave rise to a new type of so-called Control-based Information System (ICIS), in which information in factory plants flow between the shopfloor and the upper Computer Integrated Manufacturing systems as Waldner (1992) stated.

Publications

Waldner has authored several books and articles.[8][9] Books:

- 1990. CIM, les nouvelles perspectives de la production, DUNOD- BORDAS, ISBN 978-2-04-019820-6

- 1992. CIM: Principles of Computer-Integrated Manufacturing. John Wiley & Sons, ISBN 0-471-93450-X

- 2007. Nano-informatique – Inventer l’ordinateur du XXIème Siècle HERMES SCIENCE, London 2007.

- 2008. Nanocomputers & Swarm Intelligence, ISTE, London 2007 Wiley

References

- ↑ Ian David Lockhart Bogle, Michael Fairweather (2012) 22nd European Symposium on Computer Aided Process Engineering. p. 427

- ↑ Jérôme Capirossi (2011) Architecture d'entreprise. p. 278

- ↑ Journal of Applied Non-classical Logics (2007). Vol 17. p. 120

- 1 2 "CIM: Principles of Computer Integrated Manufacturing," Jean-Baptiste Waldner, John Wiley & Sons, 1992.

- ↑ Oliveira, José António Barata de. "Coalition based approach for shop floor agility–a multiagent approach." (2003). p. 2.11

- ↑ Waldner, Jean-Baptiste (September 1992). CIM : Principles of Computer-Integrated Manufacturing. London: John Wiley & Sons. pp. 128–132. ISBN 0-471-93450-X.

- ↑ Machado, Ricardo J., João M. Fernandes, and Henrique D. Santos. "An object-oriented approach to the co-design of industrial control-based information systems." 4th APCA Portuguese Conference on Automatic Control (CONTROLO 2000). 2000.

- ↑ Jean-Baptiste Waldner on Google Scholar.

- ↑ Jean-Baptiste Waldner at DBLP Bibliography Server

External links

| Wikimedia Commons has media related to Jean-Baptiste Waldner. |

- Jean-Baptiste Waldner at waldner-consulting.com