NEMA connector

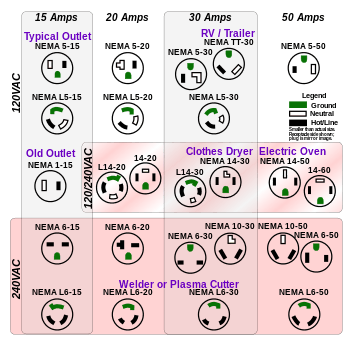

NEMA connectors are power plugs and receptacles used for AC mains electricity in North America and other countries that use the standards set by the US National Electrical Manufacturers Association. NEMA wiring devices are made in current ratings from 15 to 60 amperes (A), with voltage ratings from 125 to 600 volts (V). Different combinations of contact blade widths, shapes, orientation, and dimensions create non-interchangeable connectors that are unique for each combination of voltage, electric current carrying capacity, and grounding system.

NEMA 1 (two-prong, no safety ground) and NEMA 5 (three-prong, with safety ground pin) connectors are used for commonplace domestic electrical equipment; the others are for heavy duty or special purposes such as use in data centers.[1] NEMA 5-15R is the standard 15 A capacity electric receptacle (outlet) found in the United States. Similar and interchangeable connectors are used in Canada and Mexico.

The dimensional standard for electrical connectors is ANSI/NEMA WD-6 and is available from the NEMA website.[2]

NEMA nomenclature

There are two basic classifications of NEMA device: straight-blade and locking. The straight-blade 5-15 and 5-20 are found nearly everywhere in countries using the NEMA standards, and are intended for supplying lighter-duty, general-purpose electrical devices. Twist-locking types are used for heavy industrial and commercial equipment, where increased protection against accidental disconnection is required. Numbers prefixed by "L" are curved-blade, twist-locking connectors; others are straight blade and non-locking. The metal conductive blades are sometimes informally called "prongs" (as in "3-prong plug").

The numeral preceding the hyphen in NEMA nomenclature indicates the configuration, that is, the number of poles, number of wires, voltage, and whether single- or three-phase. A grounding type of device is described as two-pole, three-wire; or four-pole, five-wire; etc. A non-grounding device may be two-pole, two-wire; or three-pole, three-wire; etc.

The numeral following the hyphen is the rating of the device in amperes. The number is followed by the letter R to indicate a receptacle (female connector) or the letter P to indicate a plug (male connector).

As an example, the 5-15R is the common 125 V two-pole, three-wire receptacle. The L5-15R, while sharing the same electrical rating, is a locking design that is not physically compatible with the straight-blade 5-15 design. The 5-30 has the same two-pole, three-wire configuration and 125 V rating, but is rated 30 A.

Although there are several non-grounding device types in the NEMA standards, only three of them are in widespread use today. These are the two-pole 1-15, still in use in millions of buildings built before the 1960s, and the three-pole 10-30 and 10-50.

The small hole near the end of the power (non-ground) blades of some NEMA plugs is used for convenience in manufacturing; if present, it must be of specified diameter and position.[2] Small specialized padlocks are available to fit these holes, allowing "lockout" of hazardous equipment, by physically preventing insertion of locked plugs into a power receptacle.

Blade identification

The blades of a NEMA connector are identified with:[2]

| Blade Function | Letter | Color | Notes |

|---|---|---|---|

| Ground | G | Green | |

| Neutral | W | White | |

| Phase 1 hot | X | Black | X only is single phase 120 V |

| Phase 2 hot | Y | Red | X Y is single phase (centre-tap neutral) 240 or 480 V |

| Phase 3 hot | Z | Blue | X Y Z is wye three phase 120/208 V |

Non-locking connectors

NEMA non-locking connectors all use blades of various flat and folded shapes (except for the round pins used on grounding connectors). The plugs can be detached from the receptacles by pulling back on the plug body. These connector families have been designed so that grounding connectors for 120 and 208/240 V cannot be accidentally intermated.

NEMA wall receptacles can be found installed in any orientation. Neither NEMA nor the US National Electrical Code nor the Canadian Electrical Code specify a preferred orientation, but the National Electrical Installation Standards (NECA 130-2010) specifies the ground hole should be on top. When the ground blade of a receptacle is on the bottom, the neutral blade is on the upper left and the hot blade is on the upper right. All descriptions below assume this orientation (i.e. clockwise order is ground, neutral, hot for 120 V receptacle versions; and counter-clockwise for plug versions).

NEMA 1

This "2-prong" plug and socket design, with two flat parallel non-coplanar blades and slots, is used in most of North America and on the east coast of South America on lamps; consumer electronics such as clocks, radios, and battery chargers; and other double insulated small appliances that don't require grounding (earthing).

All NEMA 1 devices are two-wire non-grounding devices (hot-neutral) rated for 125 V maximum. NEMA 1-15P plugs have two parallel flat blades, 1⁄4 inch (6.35 mm) wide, 0.06 inches (1.524 mm) thick, 5⁄8–23⁄32 inch (15.875–18.256 mm) long, and spaced 1⁄2 inch (12.7 mm) apart.

Ungrounded NEMA 1-15 sockets have been prohibited in new construction in the United States and Canada since 1962, but remain in many older buildings, and this obsolete design is still available for repair use only. Since January 1, 1974, all new power outlets are required to have a ground connection, using grounded sockets (typically, NEMA 5-15 or NEMA 5-20) that accept both grounded and non-grounded plugs.[3] Replacement of obsolete NEMA-1 receptacles requires either a NEMA-5 (for two conductors plus ground wire configurations), or a NEMA-5 GFCI for two-wire non-grounded configurations (when a ground conductor is not available).

Ungrounded NEMA 1 plugs are still popular with manufacturers for certain applications, because of their low cost and compact size. They are upward compatible with widely-available grounded NEMA 5 receptacles. Standards permit ungrounded plugs where the appliance does not require grounding due to low risk of leakage current, such as on double-insulated devices.

In older plug designs, both blades were the same width, so the plug could be inserted into the socket either way around. Many plugs manufactured since 1948 are polarized; the neutral blade is wider (5⁄16 in or 7.938 mm) than the line blade, so the plug can be inserted only one way. Polarized NEMA 1-15 plugs will not fit into unpolarized sockets, which possess only narrow slots. Polarized NEMA 1-15 plugs will fit NEMA 5-15 grounded sockets, which have a wider slot for the neutral blade. Some devices that do not distinguish between neutral and line, such as internally isolated AC adapters, are still produced with unpolarized narrow blades.

The Japanese plug and socket with narrow faces appear physically identical to NEMA 1-15. The Japanese system incorporates stricter dimensional requirements for the plug housing, different marking requirements, and mandatory testing and approval by METI or JIS.[4] Cheater plug adapters allow a "3-prong" grounded NEMA 5-15 plug to be mated to a non-grounded NEMA 1-15 socket. The adapters include a spade lug to allow connecting to ground, often via the cover screw used to attach the socket faceplate.

NEMA standards exist for 1-15P, 1-20P and 1-30P plugs, and the 1-15R receptacle. There are no 1-20R and 1-30R receptacles, because 1-20P and 1-30P can mate with a corresponding NEMA 5 receptacle.

|

|

NEMA 2 (obsolete)

All NEMA 2 devices are two-wire non-grounding devices (hot-hot) rated for 250 V maximum. Although standards exist for 2-15, 2-20 and 2-30, this series is obsolete, and only Hubbell still manufactures 2-20 devices (for repair purposes).[5]

NEMA 5

All NEMA 5 devices are three-wire grounding devices (hot-neutral-ground) rated for 125 V maximum, with the 5-15, 5-20 and 5-30 being grounded versions of the 1-15, 1-20 and 1-30, respectively. The addition is a 3⁄16-inch (4.763 mm) diameter round or U-shaped ground pin, 1⁄8 in (3.175 mm) longer than the power blades (so the device is grounded before the power is connected) and located below them by 1⁄4 in (6.35 mm) edge-to-edge or 15⁄32 in (11.91 mm) center-to-center.

Compared to the 5-15P plug, the 5-20P plug has the neutral blade rotated 90° and shifted so its inner edge is approximately 1⁄2 in (12.7 mm) from the hot blade. The 5-20R receptacle may have a T-shaped neutral hole, to accept both 5-15P and 5-20P plugs. The 5-30 and 5-50 are larger, with 1 inch between power pins; 5-30 also has a bent neutral blade.[6] All of these are uncommon, as twist-locking plugs are generally used for high-current applications.

Both current blades on 5-15P plugs are nearly always narrow since the ground pin enforces polarity. If the ground pin is removed to make it fit a 1-15R outlet or extension cord, the line/neutral polarity is lost. 1-15P plugs are also compatible with 5-15P sockets. In this case, the socket retains polarity enforcement. Cheater plugs, adapters that make a 5-15P plug fit a 1-15R outlet, are readily available and retain line/neutral polarity, but violate the electrical code in some countries such as Canada.[7] Proper grounding is dependent on the outlet being an ordinary duplex receptacle with a correctly grounded center screw, and the grounding tab of the adapter being connected to that screw.

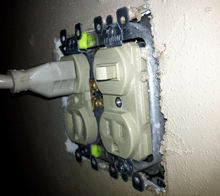

The 5-15R is by far the most common electrical outlet in North America in buildings built since the mid-twentieth century. It is usually installed in a twin duplex configuration (which may be on a common circuit, or alternatively wired with each receptacle on a separate circuit, sometimes switched). The orientation per National Electrical Installation Standards (NECA 130-2010)[8] should be with the ground hole on top. Sideways installation is also permitted; in this case, NECA 130-2010 specifies the neutral (long) slot be on top. The idea being that if something conductive were to fall on a partially inserted plug, the risk of a short-circuit would be lower (given that the receptacles are not recessed).

In 46 of the 50 United States[9] and all of Canada, tamper-resistant sockets (TRS), also known as tamper-resistant outlets (TRO), are required in new residential construction as of November 2013. These prevent contact by objects like keys or paper clips inserted into the socket.[10] This is accomplished by an interlocking mechanism that needs to have both hot and neutral blades inserted simultaneously to release the small doors blocking the slots. The grounding slot is not blocked by a door.

In stage lighting for film and theater, this connector is sometimes known as PBG (Parallel Blade with Ground), U-ground, Edison or Hubbell, the name of a common manufacturer.[11] (The name "Hubbell" can be confusing as several different connectors share this name depending on the company, industry, and use.) In the motion picture and TV production industries, an extension cord that uses this type of connector (usually with 12 AWG or 10 AWG wire)[12] is called a "stinger". Generally, lighting technicians use these extension cords to deliver power to lights rated at 2000 W or less.[13]

On the international level, the NEMA 5-15P plug and NEMA 5-15R socket are the basis for the International Electrotechnical Commission's IEC-60906-2 standard for 15 amp electrical connectors at 115±15 volts.[14]

NEMA 6

All NEMA 6 devices are three-wire grounding devices (hot-hot-ground) used for 208 and 240 V circuits and rated for 250 V maximum, with the 6-15, 6-20 and 6-30 being grounding versions of the 2-15, 2-20 and 2-30, respectively. The 6-15 resembles the 5-15, but with collinear horizontal pins, spaced 23⁄32 in (18.256 mm) center-to-center. The 20 A plug has a blade rotated 90°, and the 6-20R receptacle may have a T-shaped hole, to accept both 6-15P and 6-20P plugs.

6-15R and 6-20R receptacles are usually manufactured on the same assembly line as "Industrial" or "Commercial" grade 5-15R and 5-20R receptacles, with all 4 receptacles sharing the same "triple wipe" T contacts behind the varying faceplates. The faceplate bonded onto the receptacle determines the final configuration of the receptacle.

The 30 A plug and socket look similar to the 15 A one but larger. The higher-current versions are rare, with twist-locking plugs such as L6-30 or direct wiring more common. Generally 6-series non-locking plugs are used for such appliances as large room air conditioners, commercial kitchen equipment, and the occasional home arc welder. Single-phase 6-50 is commonly used on farms for silo unloaders, and is used with a 6-gauge flexible power cord up to 200 ft (61 m) long. Some manufacturers of electric vehicle charging stations equip their 30-40 A Level 2 EVSEs with a 6-50 plug on a short cord, though it is becoming less common, with manufacturers now favoring the more common 14-50 plug.

NEMA 6 devices, while specified as 250 V, may be used for either 208 or 240 V circuits, generally depending on whether the building has a three-phase or split-phase power supply, respectively. The NEMA 6-20R or 6-30R found in many hotel rooms is typically supplied with three-phase 208 V.

|

NEMA 7

NEMA 7 devices are 3-pin (hot-neutral-ground) connectors rated at 277 V. The 15 A 7-15 plug has the crowsfoot current carrying pins of the Type I plug, but with a U-shaped earth pin. The 7-20 version has an enlarged neutral pin. 7-30 is a larger diameter connector, with an L-shaped neutral, while the 7-50 has an enlarged neutral pin, compared with the hot.

NEMA 10

NEMA 10 devices are a deprecated type that had been popular in the United States for use with electric clothes dryers and kitchen ranges. They are classified as 125/250 V non-grounding (hot-hot-neutral), yet they are usually used in a manner that effectively grounds the appliance, though not in a manner consistent with most modern practice. This was before the requirement of a separate safety ground was incorporated in the National Electrical Code.

As commonly used, 10-30 and 10-50 plugs have the frame of the appliance grounded through the neutral blade. This was a legal grounding method under the National Electrical Code for electric ranges and clothes dryers from the 1947 to the 1996 edition. Since North American dryers and ranges have certain parts (timers, lights, fans, etc.) that run on 120 V, this means that the wire used for grounding is also carrying current. Although this is contrary to modern grounding practice, such installations remain common in older homes in the United States.[15]

NEMA 14

The NEMA 14 devices are four-wire grounding devices (hot-hot-neutral-ground) available in ratings from 15 to 60 A. Of the straight-blade NEMA 14 devices, only the 14-30 and 14-50 are common. The 14-30 is used for electric clothes dryers and the 14-50 for electric cooking ranges. Both are used for home charging of electric vehicles. The voltage rating is 250 V. They are essentially the replacements for the NEMA 10 connectors above with the addition of a separate grounding connection.

All NEMA 14 devices offer two hots, a neutral and a ground, allowing for both 120 and 240 V (or 120 and 208 V if the supply system is three-phase rather than split-phase). The 14-30 has a rating of 30 A and an L-shaped neutral blade. The 14-50 has a rating of 50 A and a straight neutral blade sized so that it does not fit in the slot of a 14-30.

NEMA 14-50 devices are frequently found in RV parks, since they are used for shore power connections of larger recreational vehicles. Also, it was formerly common to connect mobile homes to utility power via a 14-50 device. Newer applications include Tesla Motors's Mobile Connector for vehicle charging, which recommends the installation of a 14-50 receptacle for home use.[16]

|

NEMA TT-30

NEMA TT-30 (TT stands for Travel Trailer) is a 125 V, 30 A recreational vehicle standard (hot-neutral-ground), also known as RV 30. It is frequently (and sometimes disastrously) confused with a NEMA 10-30. The RV receptacle is common in nearly all RV parks in the United States and Canada, and all but the largest RVs manufactured since the 1970s use this plug. The hot and neutral blades are angled at 45° from vertical and 90° to each other, similar to NEMA 10 devices. The plug is slightly smaller than a NEMA 10 but larger than ordinary 5-15 plugs. The ground pin, however, is round, like those on straight-blade NEMA grounding devices. Referring to the diagram, the orientation is the same as the NEMA 5 plug and socket, with the receptacle neutral on the lower right. The appearance of this plug makes many people assume it is for 240 V, but this is a 120 V device. Adapters exist with the TT-30 plug on one side and a 5-15 or 5-20 socket on the other side. When the cord is detachable from the RV an L5-30 is usually used on the RV end of the cord.

Twist-locking connectors

Twist-locking connectors were first invented by Harvey Hubbell III in 1938 and "Twist-Lock" remains a registered trademark of Hubbell Incorporated,[17][18] although the term is used generically to refer to NEMA locking connectors manufactured by any company. Locking connectors use curved blades. Once pushed into the receptacle, the plug is twisted and its now-rotated blades latch into the receptacle. To unlatch the plug, the rotation is reversed. The locking coupling makes for a more reliable connection in commercial and industrial settings, where vibration or incidental impact could disconnect a non-locking connector.

Locking connectors come in a variety of standardized configurations that follow the same general naming scheme except that the designations include an "L" for "locking". Locking connectors are designed so that different voltages and current ratings can not be accidentally intermated.[19] Many specific types exist; only a few are listed below. Other types include special purpose connectors for boats, 400 Hz circuits such as used for aircraft, and direct-current applications.

One apparent disadvantage of twist-lock connectors is that in the event that the cable is accidentally pulled too hard, rather than the plug falling out of the receptacle, the exposed conductors may come out of the plug, causing dangerous shorts or shock hazards if the circuit is live. This is resolved in most cases by the connector having an integral strain relief.

NEMA ML-1

NEMA ML-1 connectors are a series of "midget" locking connectors with a maximum specified voltage of 125 V. Supply connections are intended for single-pole hot-neutral-ground circuits with a nominal voltage of 120 V. No grounding conductor is provided.

NEMA ML-2

NEMA ML-2 connectors are a series of "midget" locking connectors with a maximum specified voltage of 125 V. Supply connections are intended for single-pole hot-neutral-ground circuits with a nominal voltage of 120 V. A separate grounding conductor is provided.

NEMA ML-3

NEMA ML-3 connectors are a series of "midget" locking connectors with a maximum specified voltage of 250 V. Supply connections are intended for three-pole hot-hot-neutral circuits with a nominal voltage of 120/240 V. No grounding conductor is provided.

NEMA L5

NEMA L5 connectors are a series of locking connectors with a maximum specified voltage of 125 V. Supply connections are intended for single-pole hot-neutral-ground circuits with a nominal voltage of 120 V. L5-30 receptacles are common at marinas where power is provided for their guests.

NEMA L6

NEMA L6 connectors are used with circuits with a maximum specified voltage of 250 V. Supply connections are intended for two-pole, three wire hot-hot-ground circuits with a nominal supply voltage of 240 or 208 V, depending on phase configuration. The L6 connector does not provide a neutral connection.

L6-20 and L6-30 connectors are commonly found on in-rack power distribution units in countries where the mains supply voltage is greater than 120 V. They are also found in the US for heavy-duty 240 V equipment such as welders, where the higher supply voltage allows a lower current draw. These connectors are thus found where industrial equipment or large power tools are commonplace.

NEMA L7

NEMA L7 connectors are used with circuits with a maximum specified voltage of 277 V. Supply connections are intended for single-pole, three-wire hot-neutral-ground circuits with a nominal supply voltage of 265 V.

Typically, these connectors are found in commercial or industrial lighting circuits, especially where metal halide lamps are common.

NEMA L8

NEMA L8 connectors are used with circuits with a maximum specified voltage of 480 V. Supply connections are intended for two-pole, three-wire hot-hot-ground circuits with a nominal supply voltage of 460 V.

NEMA L9

NEMA L9 connectors are used with circuits with a maximum specified voltage of 600 V. Supply connections are intended for two-pole, three-wire hot-hot-ground circuits with a nominal supply voltage of 600 V.

NEMA L14

NEMA L14 connectors are used with circuits with a maximum specified voltage of 125/250 V. Supply connections are intended for two-pole, four-wire hot-hot-neutral-ground circuits with a nominal supply voltages of 240 or 208 V hot-to-hot and 120 V hot-to-neutral.

These connectors are common on household backup generators, and on racks of power amplifiers in large audio systems.

NEMA L15

NEMA L15 connectors are used with circuits with a maximum specified voltage of 250 V. Supply connections are intended for three-phase, three-wire with ground circuits with a nominal supply voltage of 240 V.

NEMA L16

NEMA L16 connectors are used with circuits with a maximum specified voltage of 480 V. Supply connections are intended for three-phase, four-wire L-L-L-G circuits with a nominal supply voltage of 480 V.

NEMA L17

NEMA L17 connectors are used with circuits with a maximum specified voltage of 600 V. Supply connections are intended for three-phase, four-wire L-L-L-G circuits with a nominal supply voltage of 600 V.

NEMA L18

NEMA L18 connectors are used with circuits with a maximum specified voltage of 120/208 V. Supply connections are intended for wye three-phase, four-wire L-L-L-N circuits with a nominal supply voltage of 208 V hot-to-hot and 120 V hot-to-neutral.

NEMA L21

NEMA L21 connectors are used with circuits with a maximum specified voltage of 120/208 V. Supply connections are intended for three-phase, five-wire L-L-L-N-G circuits with a nominal supply voltage of 208 V hot-to-hot and 120 V hot-to-neutral.

These three-phase connections include neutral and ground. The pin in the middle is ground, and the blade with a right angle on the tab is neutral.

NEMA L22

NEMA L22 connectors are used with circuits with a maximum specified voltage of 277/480 V. Supply connections are intended for three-phase, five-wire L-L-L-N-G circuits with a nominal supply voltage of 460 V hot-to-hot and 265 V hot-to-neutral.

NEMA L23

NEMA L23 connectors are used with circuits with a maximum specified voltage of 347/600 V. Supply connections are intended for three-phase, five-wire L-L-L-N-G circuits with a nominal supply voltage of 600 V hot-to-hot and 347 V hot-to-neutral.

Special safety features

Over time, electrical codes in the US and Canada began to require special safety features in the basic NEMA 5-15R and 5-20R configurations to address specific electric shock hazard concerns. The safety features listed below are not mutually exclusive; for example, tamper-resistant GFCI receptacle outlets are available.[20]

Ground fault circuit interrupter (GFCI) receptacles

These versions of the 5-15 or 5-20 receptacle are residual-current devices and have Test and Reset buttons (and sometimes an indicator light). In the US and Canada, they are required in many potentially wet locations, including outside outlets, bathrooms, some places in kitchens, basements, and crawl spaces.[21] They work by comparing the current going out on the hot conductor to the current returning on the neutral conductor, and disconnect the circuit if the difference exceeds 4-6 milliamperes. They are cheaper than GFCI circuit breakers and can be wired to feed additional "downstream" outlets so that putting one GFCI receptacle in a circuit protects all the plugs, lights, and switches downstream from it. They are also recommended for power tool outlets and locations where children might insert conductive objects into the receptacles.[21]

Tamper-resistant receptacles

Starting with the 2008 National Electrical Code[22] and the 2009 Canadian Electrical Code,[23] listed tamper-resistant receptacles that address electric shock hazards to children must now be installed in almost all areas of new or renovated dwellings. According to statistics cited by the NFPA, the code change adds only $40 to the cost of building an average, 75-receptacle home in the US, yet prevents shock hazards to a child that sticks a single, metal object into the receptacle. The new receptacles are expected to reduce the number of electric shocks to children because inserting a normal, two-prong electrical plug applies pressure on both sides of the outlet to open an internal, spring-loaded shutter, but a foreign object fails to do so and therefore does not make contact with the live electrical contacts.[24] However, the device can still be defeated by inserting two objects simultaneously. Despite its weaknesses, the tamper-resistant receptacle is superior to protective plastic outlet caps which must be individually installed on each receptacle (and are a choking hazard when removed), and to sliding covers that children easily learn to defeat.[22]

AFCI receptacles

The National Electrical Code has been updated for 2014 and it addresses the use of Outlet Branch Circuit (OBC) Arc Fault Circuit Interrupter (AFCI) Receptacles as an alternative to breakers when used for modifications/ extensions, as replacement receptacles or in new construction. AFCI Receptacles work to address the dangers associated with potentially hazardous arcing conditions (parallel arcs and series arcs) by interrupting power to help prevent dangerous arc-faults that may lead to an electrical fire. AFCI protection is mandated by the 2014 Code in residential family rooms, dining rooms, living rooms, kitchens, parlors, libraries, dens, bedrooms, laundry rooms, sunrooms, recreation rooms, closets, hallways or similar rooms. They are also required in dormitory units. AFCI receptacles look similar to GFCI receptacles in that they have a TEST and RESET button on the face of the device for localized testing. This saves a homeowner a trip to the breaker panel should the device trip. Unlike AFCI breakers, AFCI receptacles can be used on any wiring system, regardless of the panel. When installed as the first outlet on a branch circuit, AFCI receptacles provide series arc protection for the entire branch circuit. They also provide parallel arc protection for the branch circuit starting at the AFCI receptacle.

Surge Protective receptacles

Surge Protective Devices are designed to reduce the random energy surges of voltage transients and electrical noise on the power supply line that are damaging to sensitive electronics such as TVs, computers and smart appliances. They are available for 120 V, 15/20 A applications, in different form factors such as surge protective receptacles in single, duplex, four-in-one, and six outlet configurations as well as surge protective power strips. These devices provide point-of-use protection and are the last line of defense in a whole house surge protection network.

Weather-Resistant receptacles

Weather-resistant (WR) receptacles are made of UV stabilized thermoplastic with high cold impact resistance to withstand the elements. Required by the 2008 National Electrical Code® in outdoor damp or wet locations, WR receptacles should be installed in patio, deck and pool areas. They are available in a variety of models including GFCI and tamper-resistant. For added protection, WR receptacles should be housed in Extra-Duty While In-Use or Weather-Resistant Covers. These covers are ruggedly constructed to seal out moisture, dust, debris and insects, while providing easy access to receptacles to allow homeowners to use power tools, trimmers, sprinkler systems and pumps with confidence and improved safety.

Leak-current detection and interruption (LCDI) cordsets

Damaged power cords of portable air conditioners cause many electrical fires and about 350 deaths per year. To combat this, each portable air conditioner sold in the United States is now required to have a leakage current detector interrupter (LCDI) or ground-fault circuit interrupter (GFCI) protective device built into its power cord. The device can be integral with the power plug, or a separate module within 12 inches of the plug. An LCDI cord has a fine wire mesh around the conductors, and circuitry to detect current leaking from the conductors to the mesh, which would happen if the cord were damaged or frayed. The plugs are normal NEMA 5-15, 5-20, 6-15, 6-20 or 6-30 plugs, depending on the air conditioner, typically molded-on plugs. The protection device is equipped with "Test" and "Reset" buttons on the housing.

Color code

The color of a device neither identifies its voltage class nor power system. Because the colors are not identified by national standards, the purpose of color-coding a receptacle is set by the building owner. In this case, building owners may select brown, ivory, white, almond, grey, and black receptacles in the 5-15 configuration to blend with the decor of a room.

However, although colors are not standardized by NEMA, some industries utilize colors for certain applications, following de facto standards:

- A receptacle with a green dot is a so-called "hospital grade" device; such devices are tested to survive harder use than wiring devices intended for residential or commercial purposes.

- Per UL Standard ANSI/UL 498, a receptacle (any color) with an orange triangle, is an isolated ground (IG) device, where the grounding pin of the receptacle is connected to ground independently of the frame of the receptacle and wiring outlet box. This is also a requirement of the National Electrical Code (NFPA 70), Article 406. While neither UL nor the CSA require the face of the receptacle to be a specific color, most IG receptacles are orange.[25]

- A blue receptacle may indicate built-in surge suppressors.

- A red receptacle may indicate a special-service outlet such as one connected to an emergency standby power source.

- At least one manufacturer makes a yellow receptacle, which identifies it as corrosion-resistant.

Break-away tabs

Most duplex receptacles have metal tabs connecting the top and bottom outlets. These tabs are pre-scored so that they can be broken off to allow the top and bottom receptacles to be wired onto separate circuits.[26] This may allow for one switched outlet for a lamp, or for two separate supply circuits when heavy loads are anticipated. Two branch circuits may optionally share a common neutral wire terminating on duplex receptacles, a condition sometimes referred to as "split-wiring", "split-receptacle",[27] or "half-split".

Neglecting to break off the tabs when replacing a split receptacle can disable a switched outlet, or cause a short circuit, or accidentally parallel two circuits, depending on how the receptacle had been wired.

Obsolete devices

Original Hubbell Plug and receptacle

An early American electrical plug and socket was invented by Harvey Hubbell and patented in 1904. Hubbell's first design was a socket which screwed into a lampholder (like the early lampholder plugs), but with a separable plug with pins or blades (U.S. Patent 774,250). The 1906 Hubbell catalog shows this plug with a flush mounting socket for use in wall or floor. Other manufacturers adopted the Hubbell pattern, and by 1915 they were widespread.[28][29]

American 125 V, 15 A / 250 V, 10 A "Australian" style

A patent for this obsolete plug and socket was filed in 1915 under US Patent 1,179,728.[30] It predated the NEMA sockets and plugs, but is similar to NEMA 10-20. The plugs and sockets used in countries such as Argentina, Australia and China are based on this type and are physically compatible.

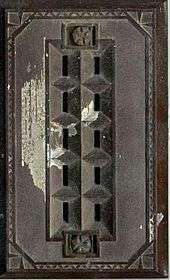

NEMA 1-15 style 5-receptacle socket

This is a 5-way socket from c. 1928, and is able to accept modern ungrounded polarized NEMA 1-15 plugs. The socket is obsolete, as the current NEMA standard only allows a maximum of 3 sockets in a single receptacle unit.

NEMA 1-15 "lightswitch" style socket

This is a rare lightswitch style 1-15 outlet. It has one vertical socket, and it can accept modern ungrounded NEMA 1-15 plugs. It is obsolete as it has little insulation, thus is a minor fire hazard when used with high-wattage devices.

Related standards

The dimensions and configurations for NEMA connectors are given in ANSI/NEMA standard WD-6.[2] Underwriters Laboratories maintains UL Standard 498,[31] which specifies construction performance (e.g.: durability, electrical safety, and fire-resistance) for NEMA connectors. These additional requirements allow connectors to be manufactured to be compliant with the National Electrical Code. The Defense Logistics Agency and General Services Administration maintain Federal Specification W-C-596[32] and its associated specification sheets. This specification references WD-6 and UL 498, and provides additional durability and electrical safety performance criteria for connectors intended for military use.

See also

- AC power plugs and sockets

- IEC 60320, an international standard for power "inlet" connectors on equipment

- Mains electricity by country

References

- ↑ How PDU Whips Work

- 1 2 3 4 ANSI/NEMA WD-6 Wiring Devices Dimensional Specifications

- ↑ http://www.webcitation.org/5nbLseFj6

- ↑ JIS C 8303-1993, Plugs and Receptacles for Domestic and Similar General Use, Japanese Standards Association, 1993

- ↑ "Hubbell catalog, NEMA 2" (PDF).

- ↑ NEMA Locking Configuration Chart

- ↑ Electrical Safety | novascotia.ca

- ↑

- ↑ Tamper-Resistant Receptacles — A Successful Adoption (PDF), retrieved 19 November 2013

- ↑ Child outlet safety, archived from the original on 22 January 2009, retrieved 21 January 2009

- ↑ Drew Campbell Technical Film and Tv for Nontechnical People, Skyhorse Publishing Inc., 2002 ISBN 1581159986 Chapter 9

- ↑ Campbell, Drew (2002). Technical Film and TV for Nontechnical People. Allworth. p. 133. ISBN 1-58115-229-9. Retrieved 2010-02-16.

- ↑ Box, Harry C. (2003). Set Lighting Technician's Handbook: Film Lighting Equipment, Practice, and Electrical Distribution (3rd ed.). Focal. p. 20. ISBN 0-240-80495-3. Retrieved 2010-02-16.

- ↑ "IEC 60906-2:2011 IEC Webstore". webstore.iec.ch. Retrieved 2016-04-13.

- ↑ Receptacle Roundup IV: NEMA 10-30 and 14-30

- ↑ "TeslaMotors.com: Go Electric - Ready, Set, Charge". Tesla Motors, Inc. Retrieved 7 June 2013.

- ↑ Hubbell Corporate History

- ↑ Hubbell Corporate History

- ↑ Hubbell Twist-Lock Wiring Devices and Safety Enclosures

- ↑ "Tamper Resistant Receptacles: The New Standard of Electrical Safety" (PDF). Hubbell Wiring Systems. Retrieved 18 October 2009.

- 1 2 "GFCIs Fact Sheet" (PDF). US Consumer Product Safety Commission. Retrieved 2010-05-04.

- 1 2 "Tamper-Resistant Electrical Receptacles" (PDF). National Fire Protection Association. Retrieved 18 October 2009.

- ↑ "Frequently Asked Questions". Child Safety Outlet. Retrieved 18 October 2009.

- ↑ "Hospital Grade Devices: Tamper Resistant Receptacles" (PDF). Pass and Seymour Legrand. Retrieved 18 October 2009.http://www.passandseymour.com/pdf/F10.pdf

- ↑ NEMA. "Application Guide for Isolated Ground Wiring Devices". www.nema.org. Retrieved 2016-03-26.

- ↑ Books.Google.com

- ↑ Winnipeg.ca

- ↑ "History". Hubbell. 2009. Retrieved 20 March 2010.

- ↑ Crist (2005). "Sockets" (tutorial). Mosaic shades. Retrieved 14 September 2007.

- ↑ Patent Images

- ↑ UL 498 (2010-05-18). "Attachment Plugs and Receptacles". Retrieved 2014-07-06.

- ↑ W-C-596 (2014-05-25). "Connector, Electrical, Power, General Specification for". Retrieved 2014-07-06.

External links

| Wikimedia Commons has media related to National Electrical Manufacturers Association standards. |

- NEMA Chart at mahonkin.com

- NEMA Chart at generatorjoe.net