Thermal expansion valve

A thermal expansion valve (often abbreviated as TEV, TXV, or TX valve) is a component in refrigeration and air conditioning systems that controls the amount of refrigerant flow into the evaporator thereby controlling the superheat at the outlet of the evaporator. Thermal expansion valves are often referred to generically as "metering devices".

Description

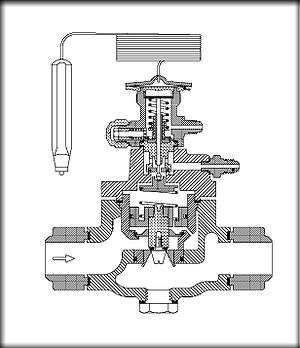

Flow control, or metering, of the refrigerant is accomplished by use of a temperature sensing bulb, filled with a similar gas as in the system, that causes the valve to open against the spring pressure in the valve body as the temperature on the bulb increases. As the suction line temperature decreases, so does the pressure in the bulb and therefore on the spring causing the valve to close. An air conditioning system with a TX valve is often more efficient than other designs that do not use one.[1]

A thermal expansion valve is a key element to a heat pump; the cycle that makes air conditioning, or air cooling, possible. A basic refrigeration cycle consists of four major elements, a compressor, a condenser, a metering device and an evaporator. As a refrigerant passes through a circuit containing these four elements, air conditioning occurs. The cycle starts when refrigerant enters the compressor in a low-pressure, moderate-temperature, gaseous form. The refrigerant is compressed by the compressor to a high-pressure and high-temperature gaseous state. The high-pressure and high-temperature gas then enters the condenser. The condenser converts the high-pressure and high-temperature gas to a high-pressure liquid by transferring heat to a lower temperature medium, usually ambient air.

The high pressure liquid then enters the expansion valve where the TX valve allows a portion of the refrigerant to enter the evaporator. In order for the higher temperature fluid to cool, the flow must be limited into the evaporator to keep the pressure low and allow expansion back into the gas phase. The TXV has sensing bulbs connected to the suction line of the refrigerant piping. The gas pressure in the sensing bulbs provides the force to open the TXV, therefore adjusting the flow of refrigerant and the superheat. [2]

Function in a refrigeration cycle

Expansion valves are flow-restricting devices that cause a pressure drop of the working fluid. The valve needle remains open during steady state operation. The size of the opening or the position of the needle is related to the pressure and temperature of the evaporator. There are three main parts of the expansion valve that regulate the position of the needle. A sensor bulb, at the end of the evaporator, monitors the temperature change of the evaporator. This change in temperature creates a change in pressure on the diaphragm.

For example, if the temperature in the evaporator increases, the pressure in the diaphragm increases causing the needle to lower. Lowering the needle allows more of the working fluid into the evaporator to absorb heat. The pressure at the inlet of the evaporator affects the position of the needle and prevents the working fluid from flowing back into the compressor. Since the pressure before the valve is higher than the pressure after the valve, the working fluid naturally flows into the evaporator. The pressure at the inlet of the evaporator acts on the diaphragm. There is also a spring providing a constant pressure closing the valve needle. The spring constantly restricts the amount of working fluid entering the evaporator.

The pressure spring can be adjusted to increase or decrease pressure based on temperature needs. The pressure created by the spring acts on the opening of the valve. When the pressure of the sensor bulb acting on the diaphragm is greater than the combined pressure of the evaporator and spring, the valve opens to increase the flow rate of the working fluid. An increase of flow rate lowers the temperature of the evaporator and allows for more heat absorption.

Types

There are two main types of thermal expansion valves: internally or externally equalized. The difference between externally and internally equalized valves is how the evaporator pressure affects the position of the needle. In internally equalized valves, the evaporator pressure against the diaphragm is the pressure at the inlet of the evaporator, whereas in externally equalized valves, the evaporator pressure against the diaphragm is the pressure at the outlet of the evaporator. Externally equalized thermostatic expansion valves compensate for any pressure drop through the evaporator.[3]

Internally equalized valves can be used on single circuit evaporator coils having low pressure drop. Externally equalized valves must be used on multi-circuited evaporators with refrigerant distributors. Externally equalized TXVs can be used on all applications; however, an externally equalized TXV cannot be replaced with an internally equalized TXV.[4]

References

- ↑ https://books.google.com/books?id=eS_2UGJVA2EC&lpg=PR8&ots=bfW0x_ObE&pg=PA445 Refrigeration & Air Conditioning Technology

- ↑ http://www.scribd.com/doc/15509399/04-Refrigeration-Cycle-A-Trane-Air-Conditioning-Clinic

- ↑ "Flow Control-Contractor Tip Card" (PDF). www.emersonclimate.com. Emerson Climate Technologies. Retrieved 16 June 2014.

- ↑ "Thermostatic Expansion Valves" (PDF). sporlanonline.com. Parker Hannifin Corporation, Sporlan Division. Retrieved 16 June 2014.