Warp (weaving)

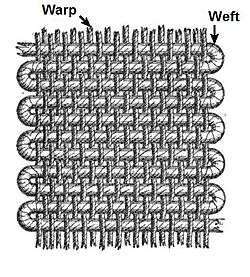

In weaving cloth, the warp is the set of lengthwise yarns that are held in tension on a frame or loom. The yarn that is inserted over-and-under the warp threads is called the weft, woof, or filler. Each individual warp thread in a fabric is called a warp end or end.[1][2] Warp means "that which is thrown away"[3] (Old English wearp, from weorpan, to throw, cf. German werfen, Dutch werpen).

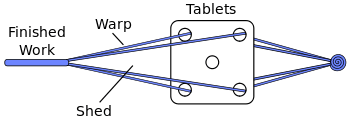

Very simple looms use a spiral warp, in which a single, very long yarn is wound around a pair of sticks or beams in a spiral pattern to make up the warp.[4]

Because the warp is held under high tension during the entire process of weaving and warp yarn must be strong, yarn for warp ends is usually spun and plied fibre. Traditional fibres for warping are wool, linen, alpaca, and silk. With the improvements in spinning technology during the Industrial Revolution, it became possible to make cotton yarn of sufficient strength to be used as the warp in mechanized weaving. Later, artificial or man-made fibres such as nylon or rayon were employed.

While most people are familiar with weft-faced weavings, it is possible to create warp-faced weavings using densely arranged warp threads. In warp-faced weavings, the design for the textile is in the warp, and so all colors must be decided upon and placed during the first part of the weaving process and cannot be changed. Warp-faced weavings are defined by length-wise stripes and vertical designs due to the limitations of color placement. Many South American cultures, including the ancient Incas and Aymaras used a type of warp-faced weaving called backstrap weaving, which uses the weight of the weaver's body to control the tension of the loom.[5]

Notes

References

- Barber, E. J. W. (1991). Prehistoric Textiles. Princeton University Press. ISBN 0-691-00224-X.

- Burnham, Dorothy K. (1980). Warp and Weft: A Textile Terminology. Royal Ontario Museum. ISBN 0-88854-256-9.