Bonawe Iron Furnace

The Bonawe Iron Furnace, also called the Lorn Furnace,[1] was an industrial complex in the middle of the eighteenth century with the aim of producing pig iron. Central to this complex was a furnace that was heated by charcoal. The complex was located at the site Bonawe in the District Lorn of the Argyll and Bute region of Scotland.

History

The industrial complex was built in 1753[2] by the small English firm of Richard Ford,[3] called the Newland Company. The site was chosen because there was enough wood in the area for the production of charcoal, as well as the fact that there was enough pressure from water to drive a water wheel. As the company itself was established in Cumbria, the blast furnace was managed by a local representative of the firm. During construction, the complex had many materials brought in from Cumbria.

For the furnace to produce pig iron, it had to first be brought up to temperature, which took about one week. The oven was used almost continuously for nine months at a time.

The complex employed as many as 600 people at the height of its operation. The majority of the staff were needed for the collection of the timber and the manufacture of the charcoal. The daily output could reach up to 2500 kilograms of pig iron and the annual production was about 700,000 kilograms. As the complex did not include a forge, finished iron products could not be manufactured, with the exception of simple objects such as cannonballs. The majority of the pig iron was taken to offices of the Newland Company in Cumbria to be shipped for further processing.

As of 1750, the use of the blast furnace coke came in on a corridor. The first blast furnace in Scotland which made use of coke was built in 1759 near Falkirk. This new development in the production of iron in the complex made Bonawe less profitable. In the nineteenth century production fell sharply and the complex was closed in 1876.

Construction

The part of the complex that was needed for the production of the pig iron consisted of four separate buildings. Two of these buildings were used for the storage of charcoal, one for the storage of iron ore, and one for the housing of the actual melting furnace. In addition to these four buildings that had a central role, there were other buildings that were associated with the complex, such as buildings for the accommodation of workers, a home for the local representative of the Newland Company, and an aqueduct. There was also a pier for the supply of raw materials and shipping of finished product.

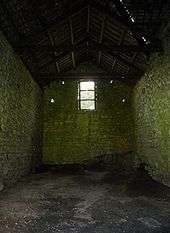

Storage of charcoal

There were two buildings for the storage of charcoal, but they also contained room for the storage of other products. The bark of felled trees was sold in turn to tanneries. The buildings were built on a slope, so the roof at the rear of the building was close to the ground. This made it easy to bring in new stocks to the rear side of the building. At the front, where the facade was much higher, it was simpler to remove the products from the building through the doors at ground level. The total storage capacity of these two buildings together was more than 2500 cubic meters.

Storage of iron ore

This building was built on a slope to facilitate loading and unloading. In this building were hematite and other minerals, limestone and stored. All of these products were needed in the preparation of pig iron.

Blast furnace

This building was central to the function of the entire complex. The raw materials were placed in the oven from the southern wing of the building, which was designated as the charging house. The large door of this wing faced south. The stored commodities were kept in three other buildings. North of the smelter was a wing equipped with bellows, which continuously supplied air to the furnace. This wing was designated as the blowing house. On the eastern exterior wall of the house was a water wheel which kept the bellows in constant motion. The water for the wheel was raised from the river Awe via an aqueduct. On the west, side of the furnace was a third wing, called the casting house. In this latter wing, the molten iron was poured into pig iron rods. Also, the slag, a by-product of the production of pig iron, arrived at this side of the oven to the outside.

Management

Bonawe Iron Furnace is managed by Historic Scotland.

References

- ↑ Mark Bowden (1 January 2000). Furness Iron: The Physical Remains of the Iron Industry and Related Woodland Industries of Furness and Southern Lakeland. English Heritage. ISBN 978-1-873592-47-2.

- ↑ G. P. Stell; Geoffrey D. Hay (31 December 1984). Bonawe Iron Furnace. HMSO.

- ↑ T. C. Smout (11 May 2005). Exploring Environmental History: Selected Essays: Selected Essays. Edinburgh University Press. pp. 91–. ISBN 978-0-7486-3514-6.

Externe links

- (en) RCAHMS - Bonawe Ironworks

- (en) Undiscovered Scotland - Bonawe Iron Furnace

- (en) Historic Scotland - Bonawe Historic Iron Furnace

Coordinates: 56°26′13″N 5°13′48″W / 56.4370°N 5.2299°W